Technological data

|

Item

|

Name

|

Unit

|

Data

|

Remark

|

|

1

|

Max bending capacity

|

mm

|

Ordinary Steel

|

Φ75×3t

|

|

|

Stainless steel

|

Φ70×3t

|

|

Square steel

|

50.8 X 50.8 x 2

|

|

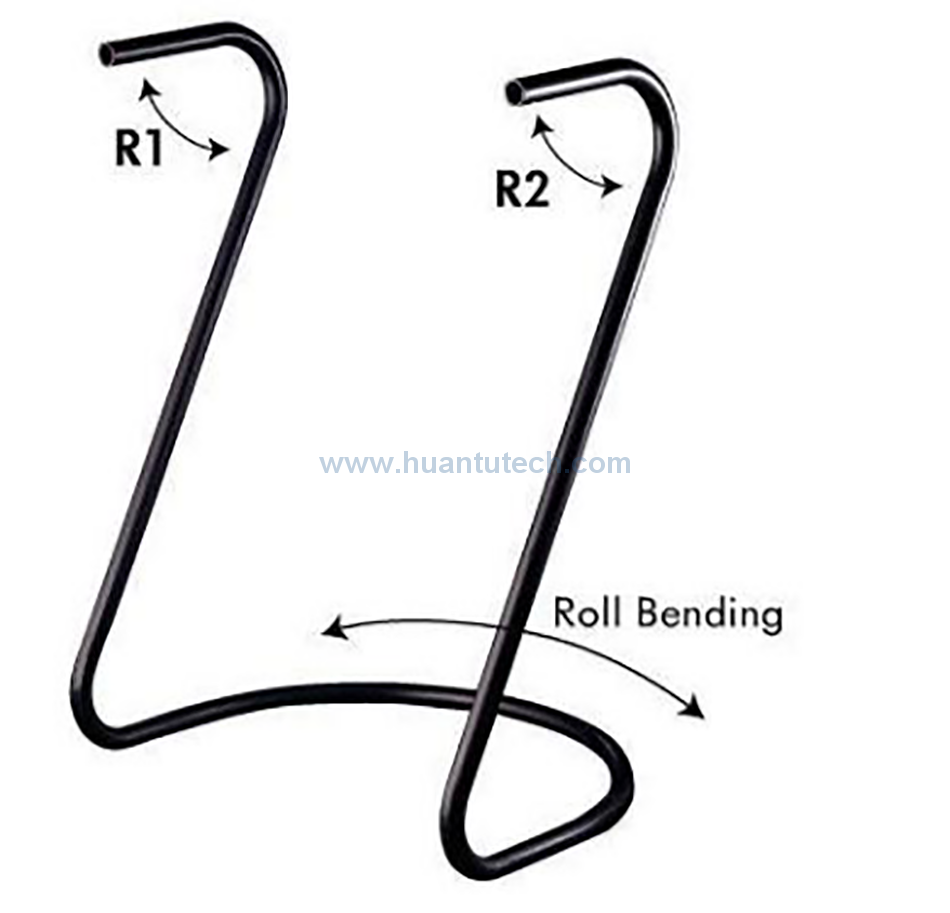

2

|

Max bending radius

|

Bending radius by winding

|

Round pipe

|

mm

|

1.5 x OD – 5 X OD

|

Can according to customer’s requirement

|

|

Rectangle pipe

|

1.5 X OD – 5 X OD

|

|

Bending radius by pushing

|

Round pipe

|

6 X OD -∞

|

|

Rectangle pipe

|

6 X OD -∞

|

|

4

|

Max feeding length

|

mm

|

6000

|

Can according to customer’s requirement

|

|

5

|

Max bending degree

|

Degree

|

190

|

|

|

6

|

Control Panel

|

|

PLC +touch screen

|

|

|

7

|

Accuracy

|

feeding

|

mm

|

±0.1

|

|

|

rotary

|

Degree

|

±0.1

|

|

|

bending

|

Degree

|

±0.1

|

|

|

8

|

Rotary servo motor power

|

kW

|

1

|

Japan Mitsubishi

|

|

9

|

Feeding servo motor power

|

Kw

|

7

|

Japan Mitsubishi

|

|

10

|

Bending servo motor power

|

Kw

|

11

|

Japan Mitsubishi

|

|

11

|

Horizontal positioning of bending console

|

Kw

|

1

|

|

|

12

|

Voltage

|

400 V,50HZ,3 Phase

|

|

14

|

Oil motor power

|

Kw

|

6

|

|

|

19

|

Oil cooler

|

L/Min

|

150

|

|

|

21

|

Machine weight

|

Kg

|

5500

|

|

|

22

|

Machine size

|

mm

|

5500×1500×1750

|

|

|

25

|

Warranty time

|

month

|

14

|

|

Configuration (can according to the customer requirements)

|

Item

|

Supplier

|

|

Magnetic exchange valve

|

Japan Yuken

|

|

Spillover Valve

|

Japan Yuken

|

|

Servo motor

|

Japan Mitsubishi

|

|

Servo Driver

|

Japan Mitsubishi

|

|

PLC

|

Japan Mitsubishi

|

|

Feeding gear

|

Germany Atlanta

|

|

Touch Screen

|

Taiwan smart face

|

|

Vane Pump

|

NOVA(Sino-America Joint venture)

|

|

Linear guide

|

Korea SBC

|

|

Sealing element

|

Taiwan DZ-UN

|

|

Reducer

|

Taiwan PHT

|

|

AC contactor

|

France Schneider Electrical

|

|

Thermal overload relay

|

France Schneider Electrical

|

|

Fuse

|

France Schneider Electrical

|

|

Proximity switch

|

Japan Omron

|

|

Power switch

|

Taiwan Mingwei

|

|

Motor

|

Wuxi Taihu

|

|

Oil Pipe

|

Jiangsu Jiake

|

软件

1.Windows XP操作系统

2.伸长率补偿

3.回弹补偿及解决方法。

4.无限的程序

5.触摸屏程序

6.反复喂料功能。 (这意味着可以限制管道的长度)

7,直接送料和夹紧送料

8,回收管功能

一些功能

1.自动识别机器和工件的功率,处理既快捷又好

2.缓慢的返回芯,在手推车的推动下,改善了角钢的外观。

3.整个操作在电脑上,简单,快捷,正确

4,巴氏杀菌编程系统:在屏幕上的立体管图像上绘制和修改,使操作简单,快捷,正确

5.回弹测试:对多种管道材料的特性进行对比测试

6.单步调试功能-在模具的制造过程中仔细观察管道材料的变形。

7.自动绘制模具图形,清楚地帮助开发新产品

8.全面检查:液压/电路/驱动系统,电动机/逆变器缺相,电压,温度,油压,并自动诊断故障

9.密码,钥匙,工作时间/数量记录被用于生产管理

配件

1.1套工装

2.芯棒:1个

3.工具箱:1个

4.操作手册:我用英文设定

5.CD:1张

备件

1.密封件:1套

2.O型圈:1套

油枪:1个